News

AI-Powered Digital Transformation in Logistics: How Digital Twins Enhance Smart Warehousing and Supply Chain Efficiency

Author: Jeremy Huang

Challenges Facing the Logistics Industry Today

In recent years, the global supply chain landscape has undergone dramatic changes due to political and economic factors, yet continues to grow significantly. According to the report The Future of the Logistics Industry: Challenges and Opportunities, the global logistics market was valued at USD 8.6 trillion in 2022 and is projected to reach USD 12.6 trillion by 2027, with a compound annual growth rate (CAGR) of approximately 6.2%.

Key drivers behind this growth include the rapid rise of e-commerce, the globalization of supply chains, and the accelerated adoption of emerging technologies. However, this expansion also comes with increasing challenges such as labor shortages, rising fuel and operational costs, and heightened risks of supply chain disruptions.

Against this backdrop, traditional logistics operations—largely dependent on manual labor and rigid planning—are finding it difficult to handle increasingly complex demands efficiently. Storage and distribution systems now require greater flexibility and efficiency. This is where Digital Twin technology, which allows for virtual simulations of warehouse layouts and logistics flows, plays a vital role.

What Is a Digital Twin?

According to NVIDIA, a Digital Twin is a real-time synchronized digital replica of physical facilities and processes, continuously updated to reflect real-world conditions. It enables users to simulate and optimize operations in a virtual environment before implementation.

This technology involves sensors, the Internet of Things (IoT), AI-powered simulations, and real-time data streaming. Unlike traditional simulations—which are often one-off and limited to design-phase validation—Digital Twins provide ongoing, real-time reflection of actual operational states.

Three Key Benefits of Adopting Digital Twins

1. Warehouse Operations Optimization

In conventional logistics, warehouse space planning and process design typically rely on on-site experience and iterative testing—an approach that is time-consuming and difficult to scale. Digital Twin technology enables complete virtual replication of warehouse environments, allowing logistics managers to simulate material flows, equipment operation, and personnel movement. They can rapidly test different layout configurations to identify the optimal design.

This simulation-first approach not only accelerates the design process but also significantly reduces the costs and risks associated with physical adjustments.

2. Collaboration Between Robotics and Automation

As smart warehousing becomes more prevalent, improving the coordination and efficiency of automated systems has become a major challenge. Digital Twins allow decision logic and behavior models for robots to be trained and tested in virtual environments. There is no need to physically deploy hardware first—operational parameters and navigation paths can be optimized beforehand.

This reduces development risks and enhances the safety and efficiency of collaboration between humans and robots.

3. Supply Chain Decision Support

Beyond internal warehouse simulation, Digital Twins can be integrated across the entire supply chain, serving as platforms for real-time decision-making. By consolidating sensor data and logistics information, enterprises can gain visibility into material flow and equipment status, and respond rapidly to demand shifts or disruptions.

With predictive analytics capabilities, the system can detect potential bottlenecks or delays in advance, enabling companies to make more accurate resource allocations and implement effective risk controls—ultimately increasing supply chain resilience and agility.

Real-World Applications in Global Logistics and Manufacturing

As the technology matures, leading logistics and manufacturing companies are beginning to implement Digital Twin solutions in real-world scenarios. Germany’s logistics equipment giant KION Group has partnered with Accenture and NVIDIA to adopt the latest “Mega” Omniverse Blueprint, creating a fully simulated warehouse Digital Twin system.

KION uses NVIDIA Omniverse to build digital replicas of its warehouse facilities by integrating CAD designs, camera footage, LiDAR data, and AI-generated inputs. Their Warehouse Management System (WMS) is also linked to the Digital Twin, enabling real-time task assignments to virtual robots, such as transporting goods or navigating around obstacles.

With this simulation platform, robots can be trained in virtual scenarios—repeating cycles of perception, reasoning, decision-making, and execution—while adjusting strategies based on real-time feedback. This leads to improved efficiency and stability upon real-world deployment.

The simulation process leverages Mega Blueprint, which combines NVIDIA Isaac autonomous robotics platform with Omniverse Cloud Sensor RTX for large-scale, synchronized simulation of sensors and environments. Enterprises can test unlimited scenario combinations and train AI models using synthetic data—significantly lowering testing costs and reducing physical equipment wear and tear.

KION reports that adopting Mega Blueprint has greatly shortened warehouse construction and robot training timelines, while providing the flexibility to respond to seasonal demand changes, order fluctuations, or workforce shifts. Accenture emphasizes that integrating AI simulation into warehouse design and operations marks a critical step toward the future of “Physical AI” and Software-Defined Warehousing.

MetAI and KENMEC Bring Digital Twins to Life in Taiwan

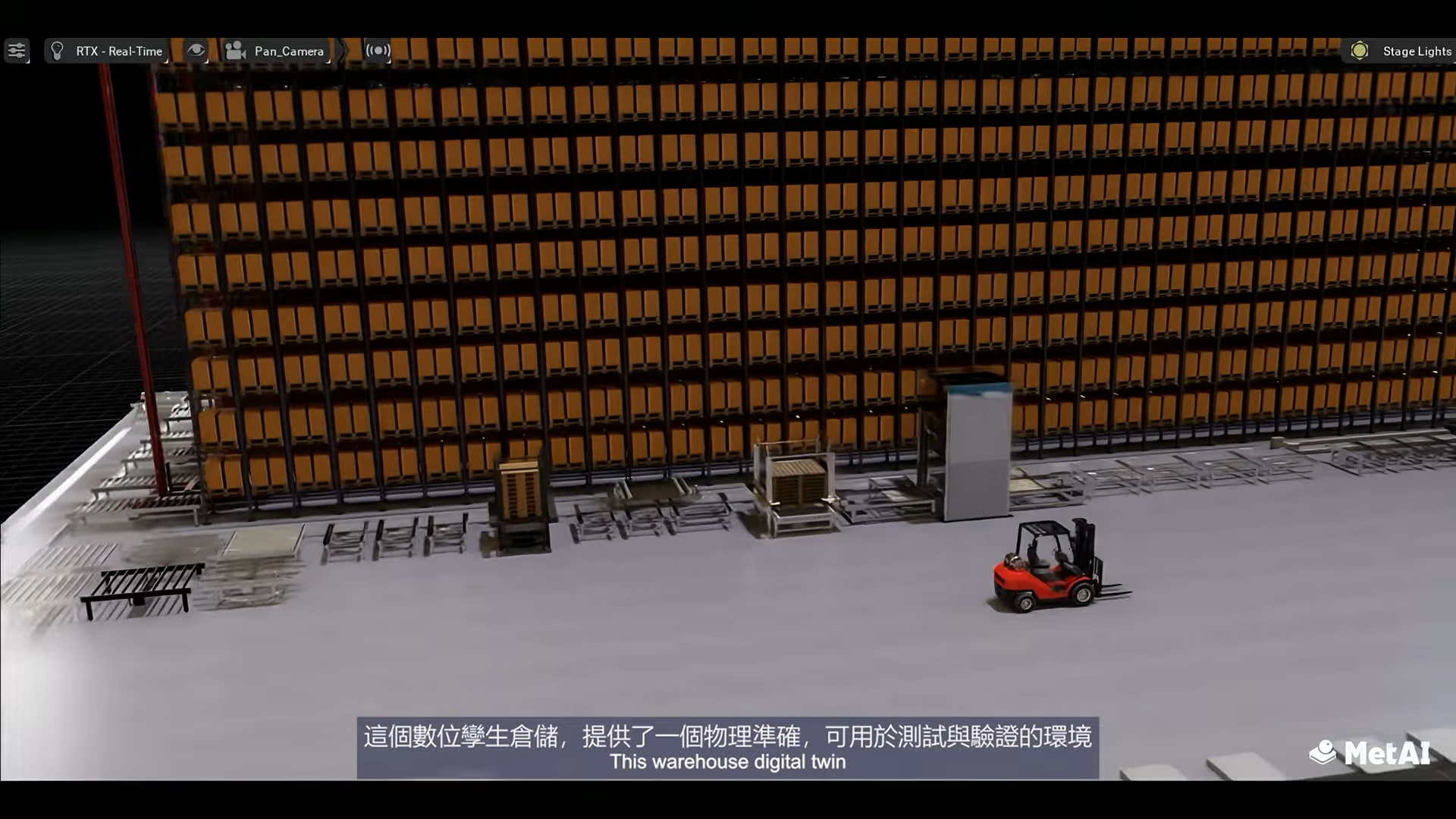

Taiwan has also seen the deployment of Digital Twin technology in logistics centers. According to a DIGITIMES report, Taiwanese AI simulation startup MetAI has partnered with industrial automation brand KENMEC to implement NVIDIA’s Omniverse “Mega” Blueprint—becoming one of the world’s first early adopters to bring this technology into real-world operations.

The two companies chose the Chyun Fong Shing Yeh Smart Logistics Center as the demonstration site, aiming to create a high-fidelity, real-time synchronized Digital Twin system with control logic verification capabilities—accelerating digital transformation in smart warehousing and smart manufacturing.

MetAI’s MetGen simulation platform can instantly convert 2D design schematics and on-site data into OpenUSD-based digital environments. It integrates a Controller Simulator to test actual PLC control logic. Meanwhile, KENMEC contributed its logistics conveyor systems, autonomous mobile robots (AMRs), smart cameras, and robotic arms to the virtual deployment.

The joint team also implemented AI agents to assist in optimizing control logic and logistics routing, ensuring each simulation scenario corresponds to the complexity of real-world operations.

This Digital Twin system completed high-precision simulation and integration testing before deployment, significantly reducing development risks and time costs while improving overall production line efficiency. Simulation results showed clear advantages in error prevention (e.g., avoiding cargo pile-ups) and workflow scheduling. The project successfully validated a Simulation-First engineering methodology, laying the technical groundwork for future applications in semiconductor AMHS systems, collaborative warehouse robotics, and AI-driven factory design—all part of the Physical AI revolution.

Conclusion

As logistics demands become increasingly complex and unpredictable, Digital Twin technology is emerging as a core driver of industry transformation. By enabling real-time simulation and validation of physical processes in a virtual environment, enterprises can reduce the costs and risks of physical testing while optimizing layout, automation, and decision-making before deployment.

From global industrial leaders to Taiwan’s smart logistics centers, real-world case studies demonstrate how Digital Twins can shorten implementation cycles, enhance operational flexibility, and boost overall supply chain responsiveness and efficiency—preparing businesses for any uncertainty ahead.

Disclaimer

The information provided in this article is for general reference only. Some content is cited from public reports and enterprise case studies and does not constitute promotion or endorsement of any specific company, product, or technology. Readers should evaluate the suitability and risks of any technology based on their own circumstances and consult with professionals if needed.

Reference

2025/09/22

The New Era of Smart Security — Global Shifts Revealed at Security Exhibition & Conference 2025

Google Unveils New AI World Model Genie 3: Capable of Generating 3D Virtual Worlds with Several Minutes of Interaction

AIoT and Cybersecurity Resilience: Leading the Next Wave of Smart Surveillance Transformation

GPT-5 Officially Released: AI Steps Into the Era of Autonomous Agents

Registration Open for the "Smart Factory AI Revolution Forum: New Perspectives on AI Assistant Implementation and Collaboration"

Google Unveils Veo 3: AI Model for High-Quality Video and Audio Generation